In an era where technological shifts are reshaping entire industries, the dramatic pivot of a former automobile production line toward high-tech defence systems stands out as a striking example of innovation and resilience. At a time when declining vehicle sales and the slow pace of electrification are challenging the automotive sector, companies like Hirsch Engineering are redefining their destinies. This metamorphosis from traditional car manufacturing to advanced weapons production offers a compelling narrative of adaptation, risk management, and excellence in engineering.

A Changing Landscape in the Automotive World

The automotive sector in Europe has been feeling the pressure from multiple fronts. Sales are dwindling, the push toward clean electric mobility is not as brisk as originally forecast, and fierce competition from emerging Chinese manufacturers is intensifying. Meanwhile, political uncertainties and shifting consumer behaviours have forced many established carmakers—and their subcontractors—to reexamine long-held strategies. Rather than remain tethered to a sinking market, several industrial players are exploring alternative routes where their core competencies remain valuable. In this evolving environment, the story of one German manufacturer serves as a beacon of transformation.

Historically renowned for its expertise in automotive engineering, Hirsch Engineering was initially part of a thriving network of subcontractors supplying high-quality components to major firms such as Audi. However, with the automobile market facing a steep decline and the electrification transition posing unprecedented technical challenges, many suppliers were forced to pivot amid inevitable layoffs and plant closures. Against this backdrop, Hirsch Engineering seized the opportunity to reposition itself in a vastly different and promising arena—defence manufacturing.

The Hirsch Engineering Case: From Cars to Cutting-Edge Weapons

In a recent interview with the esteemed newspaper Le Monde, Thomas Hirsch, the visionary behind Hirsch Engineering, detailed the strategic rationale that guided his company’s remarkable shift. Originally established in 2016 as an automotive subcontractor with a robust track record, Hirsch Engineering soon found its business model under threat from a volatile marketplace. Facing declining volumes and the disruptive forces of electrification, the company made a bold decision: transition from manufacturing traditional car parts to developing sophisticated defence systems.

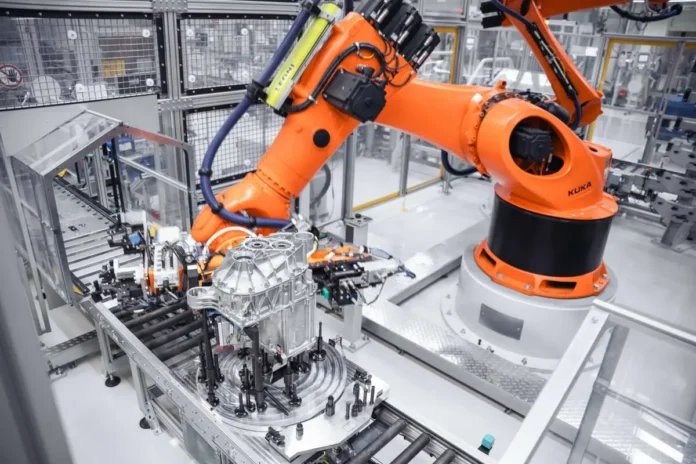

Hirsch Engineering’s journey is not merely about survival—it is a profound case study in industrial reinvention. The company leveraged its existing production lines and technical expertise to build state-of-the-art armaments, making the transition seamlessly while retaining its commitment to precision engineering. While some observers might find the move unexpected, those with insight into modern manufacturing understand that diversification and adaptability are essential strategies in times of economic turbulence.

Why Reinvention Now? A Look at the Broader Implications

The transformation witnessed at Hirsch Engineering mirrors a broader trend among industrial manufacturers striving to remain competitive in a rapidly changing world. As traditional car sales decline and the challenges of transitioning to electric vehicles persist, the need to explore alternative revenue at diverse intersections of technology becomes paramount. Manufacturing in defence not only demands rigorous standards but also offers a more stable market environment, especially in periods of economic uncertainty.

Companies that successfully navigate such shifts often invest heavily in research and development, drive innovation in automation, and employ a dynamic workforce trained in cutting-edge technologies. This kind of pivot reinforces a broader economic narrative in which manufacturing firms redefine their roles by aligning with sectors that promise sustained demand—thereby ensuring long-term viability and growth.

Comparative Analysis: Automotive Production vs. Defence Manufacturing

The following table provides a snapshot comparison of key metrics and considerations for traditional automotive production versus the new frontier of defence manufacturing:

| Parameter | Traditional Automotive Production | Defence Manufacturing |

|---|---|---|

| Market Dynamics | Volatile consumer demand; highly competitive | Stable demand driven by state contracts and innovation |

| Technical Requirements | Focus on performance, efficiency, and design | Emphasis on precision, reliability, and advanced technology |

| Investment Needs | High capital investment with longer ROI cycles | Significant R&D and streamlined production cycles |

| Regulatory Environment | Stringent safety standards; environmental regulations | Rigid government standards and security protocols |

| Growth Potential | Moderate growth amid electrification challenges | High potential, particularly during geopolitical shifts |

This comparison sheds light on why a historic automotive manufacturer might find the transition not only necessary but also potentially lucrative in the long run.

Looking Ahead: A Future Rooted in Adaptability and Innovation

The experience of Hirsch Engineering sets an inspiring example for manufacturers across the globe. By reorienting its production strategy to focus on defence applications, the company is not merely abandoning its automotive heritage—it is capitalising on its engineering prowess to create cutting-edge products tailored for a vastly different market segment. As industries worldwide grapple with the pressures of globalisation and technological evolution, such bold moves will likely become the norm rather than the exception.

The pivot from car production to defence manufacturing signals a deeper narrative about the resilience and dynamism of the engineering sector. It serves as a reminder that in times of disruption, innovation and transformation can pave the way to success. Manufacturers willing to diversify and adapt in the face of adversity will not only survive but thrive, helping to shape the future of technology and mobility.

Conclusion

This story from CommaFast illustrates how a legacy car factory can reinvent itself amid shifting market forces. Hirsch Engineering’s transition from automotive manufacturing to defence production is a testament to the enduring spirit of innovation. By leveraging technical expertise and embracing new market demands, the company has redefined its future in an industry where change is the only constant. This is a powerful example of how resilience and forward-thinking can not only adapt to disruption but also create a new realm of opportunity.